1. Customer use case of KN95 mask automatic packaging machine

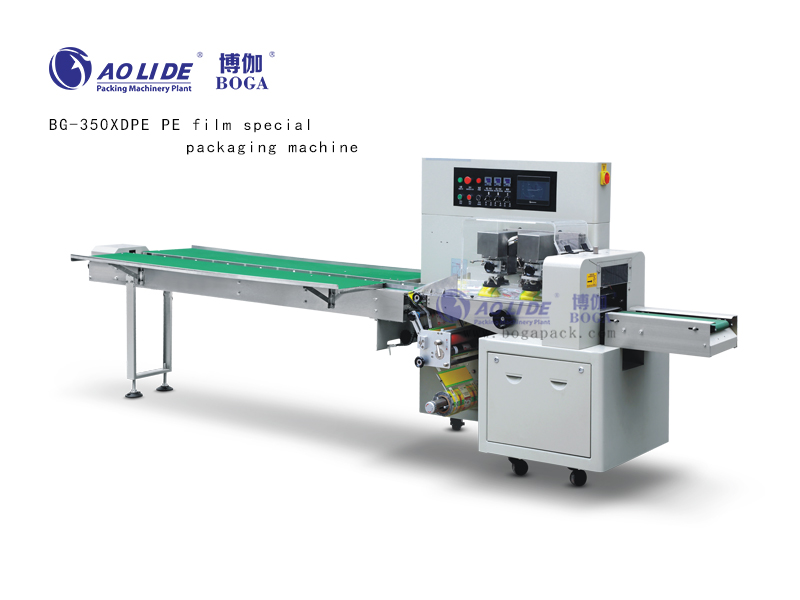

The video customer uses a fully automatic mask packaging machine produced and manufactured by Bojia to pack masks. Model: BG-350X mask packaging machine. The machine uses a servo control system flat belt, intelligent anti-aircraft material, anti-pinch material and other functions. , It is more intelligent, more practical and more worry-free than the traditional frequency conversion packaging machine.

The customer packs KN95 masks, and the packaging speed can be as high as 100 minutes per minute, which greatly improves production efficiency. Customers are undecided about the packaging effect and ease of use of our machines.

Two, BG-350 technical parameters

Packaging film width: 340mm

Bag length: automatic induction bag length

Bag making width: 50-160mm

Product height: 45-65mm

Die roll diameter: 320mm

Packing speed: 10-25m/min

Power specification: 220v, 50/60Hz, 2.8KW

Machine size: L3527xW765xH1375mm

Machine weight: 550 KG

3. Performance characteristics:

1. Three servo motors, PLC control, the bag length is set and cut immediately, no need to adjust the idling, one step is in place, saving time and film.

2. Man-machine interface, convenient and quick parameter setting, can sense automatic packaging of products, and automatically pause and wait without products.

3. The fault self-diagnosis function, the fault display is clear at a glance.

4. High-sensitivity photoelectric eye color mark tracking, digital input of the sealing and cutting position, so that the sealing and cutting position is more accurate.

5. Independent PID control of temperature, better suitable for various packaging materials.

6. Positioned stop function, no sticking to the knife, no waste of packaging film.

7. The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

8. All control is realized by software, which is convenient for function adjustment and technical upgrade, and never lags behind.

9. The length of the material is automatically sensed, the product is automatically packaged, there is no product shutdown and waiting, and no adjustment is required.

Four, optional equipment

Coding machine

hole puncher

Full stainless steel

touch screen

Inflatable device

Exhaust

No material shutdown function

Customized sealing pattern or pattern

Automatic feeding device

- Daily maintenance and cleaning of pillow-type food packaging machine

- How much is a pillow-type mask packaging machine

- KN95 mask automatic packaging machine

- Hardware packaging machinery application range

- How to choose the right pillow packaging machine for you?

- What are the differences between common pillow packaging machines?

- Seven suggestions on how to buy a frozen food pillow packaging machine

- Daily maintenance and cleaning of pillow type food packaging machine

- Prev:Hardware packaging machinery application range

- Next:How much is a pillow-type mask packaging machine